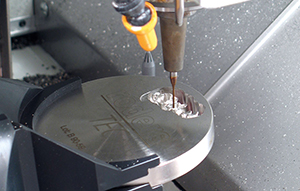

Röders’ Dental Solutions

The HSC machines from Röders have been appreciated in the tool and die making industry for many years due to their high-performance and quality machining of complex contours for various materials. In total, more than 2800 machines have been delivered to more than 50

countries.

Since 2007, these outstanding features have attracted more and more dental labs to work with this industrial machine technology. The major advantages of the machines are:

- Wear-free axis drives with linear motor technology and a very rigid design for long durability

- Extremely short machining times due to the highest machine dynamics

- Long-lasting tool life resulting in very low tool costs due to high machine stiffness and the avoidance of tool vibration

- Highest precision, also for simultaneous 5-axis machining

- All materials can be machined using one machine

- Tool length measurement, break and wear control with integrated measuring laser, automatic continuation of the next job in case of tool breakage, automatic tool change in case of wear

- Integration into Röders own manifold automation solutions possible, also after installation of the machine

- Highest service performance as all components of the machine are developed inhouse by Röders engineers

ABUTMENT

CR-CO BAR

MILLING BLANK

CR-CO DISK

RCS1 – MILLING MACHINE

AUTOMATION FOR ABSOLUTE COST MINIMIZATION