Concept Laser

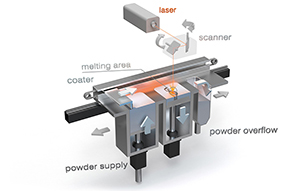

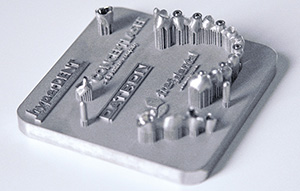

Concept Laser GmbH, founded in 2000 by Frank Herzog, is one of the world‘s leading providers of machine and plant technology for 3D printing of metal parts. Since December 2016, Concept Laser has been part of GE Additive, a division of the world’s leading digital industrial enterprise General Electric (GE). The technology driver is the patented LaserCUSING® technology from Concept Laser. The powder-bed-based laser melting of metals opens up new freedoms in the configuration of parts and permits the tool-free, economic fabrication of highly complex components in fairly small batch sizes. 3D metal printing is used to manufacture dental products such as crowns, caps, model castings and secondary structures in an economical way. Perfectly fitting dentures made from cobalt-chromium, titanium or precious-metal alloys can be manufactured virtually overnight!

In addition to first-class additive production machines, also from Concept Laser, GE Additive offers materials and extensive development consulting for various industries. GE Additive is dedicated to the further development and transformation of the industrial sector with softwaredefined plants as well as networked, adaptable and forwardlooking solutions.

LaserCUSING® Process

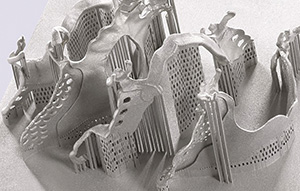

PARTIAL DENTURE

HYBRID MANUFACTURING

HIGH QUALITY DENTAL BRIDGE

M2 cusing Multilaser

Mlab cusing 200R