FOLLOW-ME! Overview

Anti- Piracy Alliance

Four leading companies in digital dentistry—CIMsystem, FOLLOW-ME! Technology GmbH, GO2cam Dental, and ModuleWorks have formed an alliance to tackle the growing threat of software piracy. This represents a joint commitment to protect patient safety, support innovation, and ensure ethical practices by eliminating piracy in digital dentistry manufacturing software.

SUPPORT

Hier finden Sie unsere FAQ’s sowie updates der hyperDENT software, trainings und die hyperDENT CAD/CAM Bibliotheken.

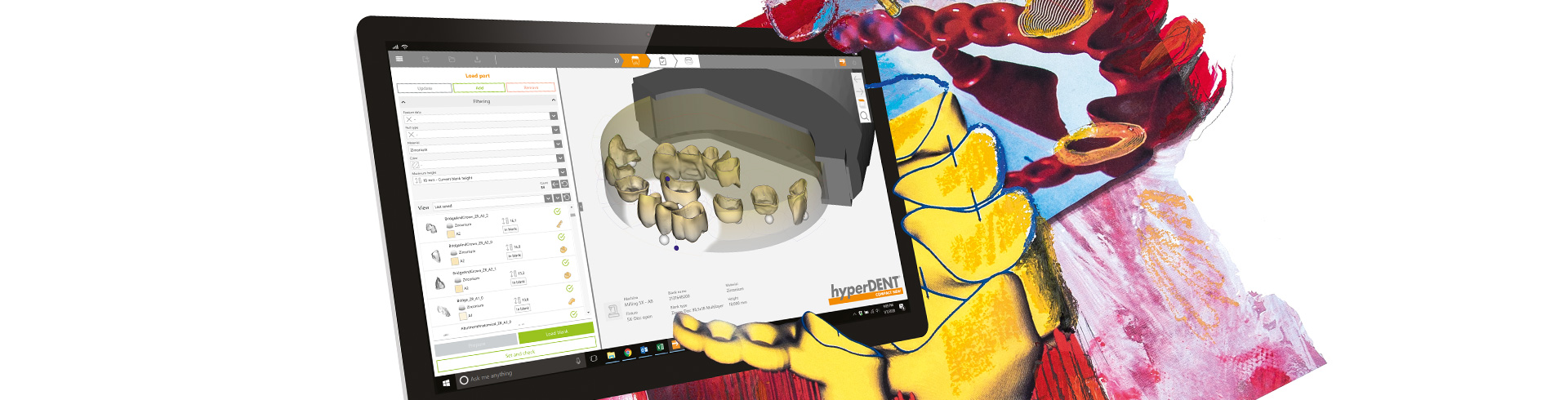

hyperDENT connect

FOLLOW-ME Technology präsentiert stolz seinen ersten Cloud-Service. Mit hyperDENT connect bieten wir eine Datentransferplattform, die den schnellen Austausch von digitalen dentalen Fertigungsdaten ermöglicht. Erleben Sie einen nahtlosen Arbeitsablauf, der die Produktivität und Genauigkeit steigert.

Unsere Anwendung bereitet CAD-Dateien, die an den Hersteller gesendet werden, automatisch inklusive Metadaten auf, was sich sehr positiv auf den nachfolgenden Produktionsprozess auswirkt.

Unsere auftragsspezifische Chat-Funktion ermöglicht Ihnen eine mühelose Kommunikation mit dem Kunden, wodurch Missverständnisse vermieden und Fortschritte beschleunigt werden. Unser Benachrichtigungssystem hält Sie mit rechtzeitigen Warnungen und Aktualisierungen auf dem Laufenden.

PARTNER

Die vertrauensvolle Zusammenarbeit mit unseren Partnern ist von zentraler Bedeutung, denn nur so können wir unser Produktportfolio gezielt weiterentwickeln, um den zukünftigen Marktanforderungen gerecht zu werden, unseren Kunden die bestmögliche Qualität zu liefern und gleichzeitig erstklassige Supportleistungen zu gewährleisten..

UNTERNEHMEN

Als Technolgieführer entwickeln wir unser Produktportfolio kontinuierlich und zukunftsweisend durch neue, intelligente Lösungen weiter, die den zukünftigen Bedürfnissen und Erwartungen unserer Partner vorgreifen.

Als Qualitätsführer legen wir großen Wert darauf, die Qualität bestehender Funktionalitäten zu 100% zu erhalten und neue Funktionalitäten mit dem gleichen Anspruch zu entwickeln.

FOLLOW-ME! News

Treffen Sie uns:

Expodental 11.-13. März 2026 in Madrid

Dental Forum 2.-4. April 2026 in Paris

AEEDC 2026:

Meet the guys from Hufschmied Zerspanungssysteme GmbH, FOLLOW-ME!, Deutsche Technik Dentallabor and Eisenbacher!

#camcad ... Mehr sehenWeniger sehen

1 KommentareComment on Facebook

With Christmas just around the corner, all headquarters employees worked in the Munich office for three days — the last ones of 2025! It was the perfect moment to look back on the year and reflect, which we did over a shared dinner. We enjoyed great conversations alongside excellent food.

#team ... Mehr sehenWeniger sehen

0 KommentareComment on Facebook

FOLLOW-ME! around the world:

Great Meetings with some of FM Koreas partners and customers during our joint annual session last week! Thank you for your kind hospitality and your loyalty to hyperDENT! ... Mehr sehenWeniger sehen

0 KommentareComment on Facebook

Visit us at Formnext, Hall 12.0, Stand B 105 ... Mehr sehenWeniger sehen

0 KommentareComment on Facebook

FOLLOW-ME! around the world:

Nice and productive annual meeting at DGShape HQ in Hamamatsu / Japan. We are looking forward to intensify our cooperation in 2026! ... Mehr sehenWeniger sehen

0 KommentareComment on Facebook

FOLLOW-ME! around the World:

Productive Meetings with our teams from FOLLOW-ME! China and FOLLOW-ME! South Asia as well as our long term Partner XTCERA in Shenzhen! ... Mehr sehenWeniger sehen

1 KommentareComment on Facebook

FOLLOW-ME! across Europe:

Nice and productive meeting with DGShape France team in Lyon yesterday. Thanks for your hospitality guys! ... Mehr sehenWeniger sehen

2 KommentareComment on Facebook

Formnext 2025 in Frankfurt.

Visit us at the Formnext on the 18th to the 21st of November 2025 in hall12 Stand B105!

#HyperDent #formnext2025 ... Mehr sehenWeniger sehen

0 KommentareComment on Facebook

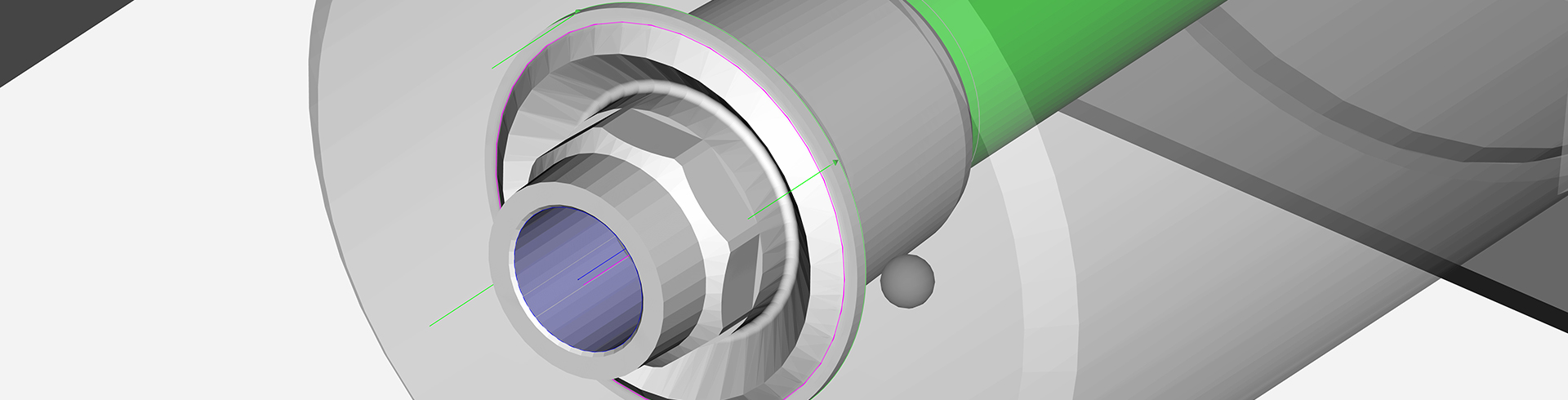

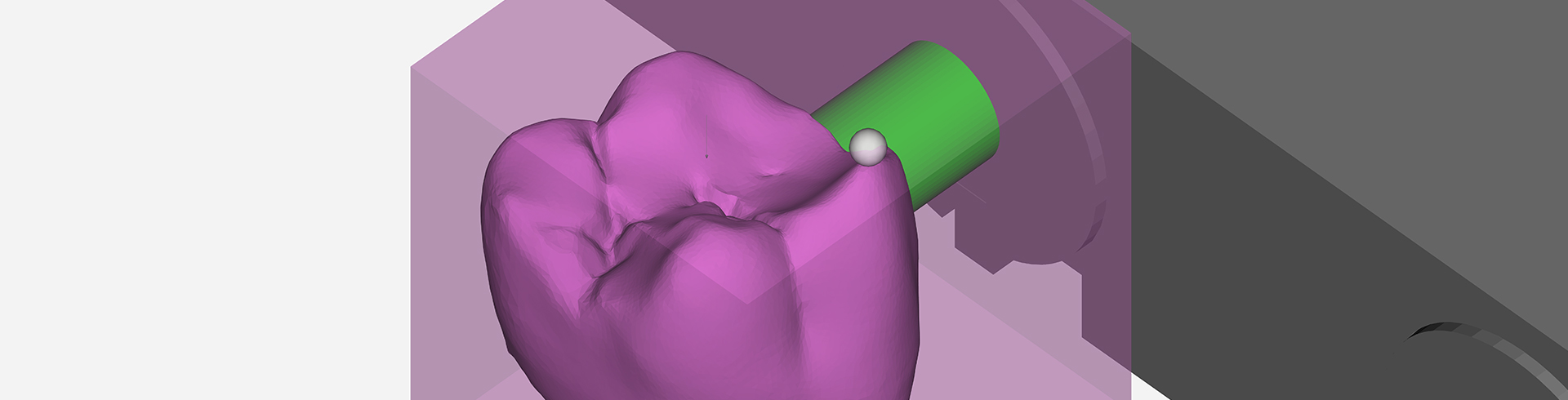

hyperDENT certifies DGSHAPE Milling machines for Power Milling Cycles!

After testing and research, hyperDENT engineers, in collaboration with DGSHAPE, have finalized the Power Milling strategy package to optimize dental production on all DGSHAPE 5X milling machines!

Experience the next level of CAD/CAM production:

With the Power Milling module from hyperDENT, you can combine roughing and finishing in a single job, perfectly matched to the Zirkonator® tool from Hufschmied Zerspannungssysteme. The CAD files are milled at full depth, ensuring an efficient, uninterrupted workflow designed for Zirconia.

Power Milling Module

With the hyperDENT PowerMilling module, you not only save valuable time, but also noticeably increase the efficiency of your production.

The bigger the piece, the greater the time saved!

Your advantages at a glance

- Significantly reduced milling times

- Perfect surfaces in a single step

- Maximum material removal

- Fewer tool changes, less set-up time

- More output - same machine runtime

Roughing and finishing in one job. Maximum depth. Minimum time. ... Mehr sehenWeniger sehen

2 KommentareComment on Facebook