FOLLOW-ME! News

IDEC 2019 | Jakarta Convention Center | Indonesia

Italian Dental Show – Colloquium Dental 2019

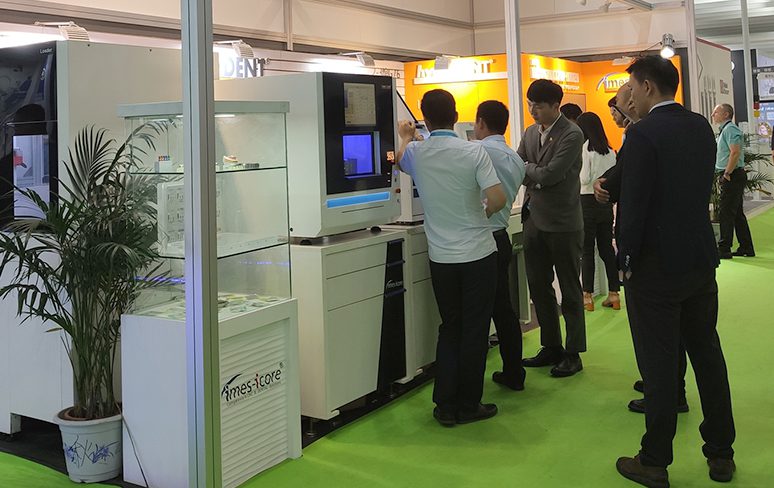

Rückblick – Sino Dental 2019

Unser Partner Rizen begleitete uns als Mitaussteller bei der diesjährigen Sino Dental in Beijing, China. Über eine Live Demonstration konnten sich potenzielle Kunden direkt an den Maschinen mit unserer CAM-Software hyperDENT vertraut machen. Das Interesse aus dem In- und Ausland war sehr groß, als unsere Vertriebsmitarbeiter und technischen Ingenieure die Einsatzmöglichkeiten von hyperDENT erklärten und Funktionen veranschaulichten. Die Messe bot zudem eine gute Gelegenheit für Kunden gezielt hyperDENT Themen zu besprechen, die FOLLOW-ME! dabei unterstützen künftige Entwicklungen zu planen und den Kundenservice weiter zu verbessern. Die Kunden äußerten sich insgesamt sehr positiv über unseren Support und zeigten großes Interesse an einer langfristigen Zusammenarbeit.