FOLLOW-ME! News

Formnext 2022

IDEM 2022

Die IDEM bot eine hervorragende Plattform für unser Unternehmen und wir trafen einige unserer aktuellen Kunden und Partner aus aller Welt. Verbessern Sie die Zusammenarbeit, tauschen Sie Ideen aus, um neue Herausforderungen anzugehen und die neuesten Markttrends zu erkunden, damit wir unsere Kompetenz aufrechterhalten, unser Wissen und unsere Fähigkeiten aktualisieren und weiterentwickeln und sicherstellen können, dass wir die weltweit führende Dentalsoftware hyperDENT sind.

Ihr FOLLOW-ME! Team, Singapore

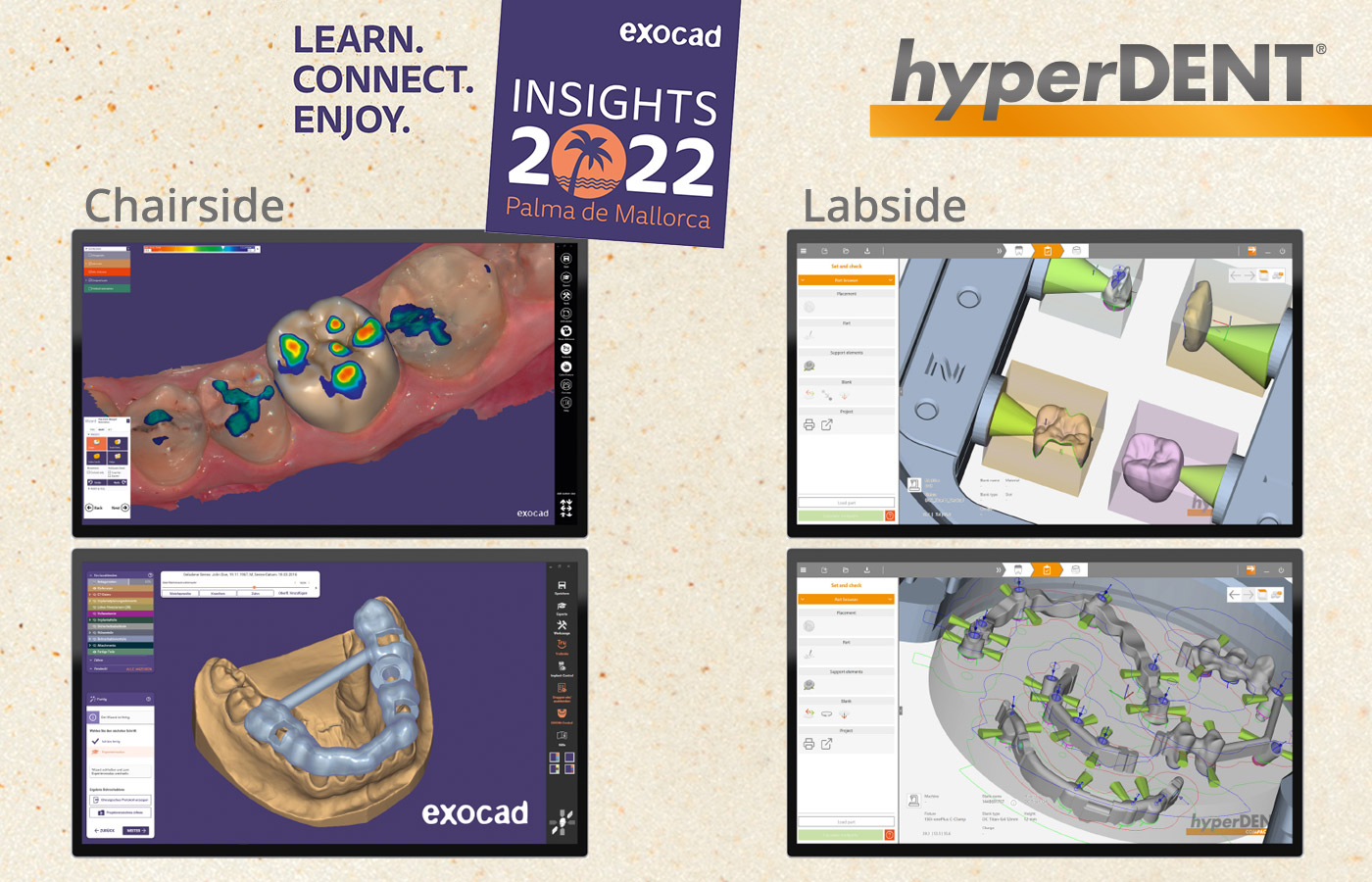

FOLLOW-ME! auf der exocad Insights Mallorca 2022

Wir freuen uns, Ihnen unsere innovativen Chaiside- und Labside-Lösungen während der exocad Insights vom 3. bis 4. Oktober 2022 auf der sonnigen Insel Mallorca, Spanien, präsentieren zu dürfen.

Chairside

hyperDENT exocad ChairsideCAD is our fully integrated blackbox solution wihin exocad.

„The integration of hyperDENT offers users the highest degree of flexibility and performance single-visit dentistry.”

Novica Savic, CCO at exocad

Labside

hyperDENT Compact is our solution for all dental lab milling machines.

„The simplified user interface with a managed workflow offers real added value to our customers.“

Dr. Ferdinand Schwenkert, CEO at FOLLOW-ME!

Formnext

15. – 18. November 2022 | Frankfurt am Main

Als führende Branchenplattform für additive Fertigung und industriellen 3D-Druck ist die Formnext internationaler Meetingpoint für die nächste Generation der intelligenten industriellen Produktion.