FOLLOW-ME! News

Bestmögliche Resultate mit hyperDENT & imes-icore Maschinen

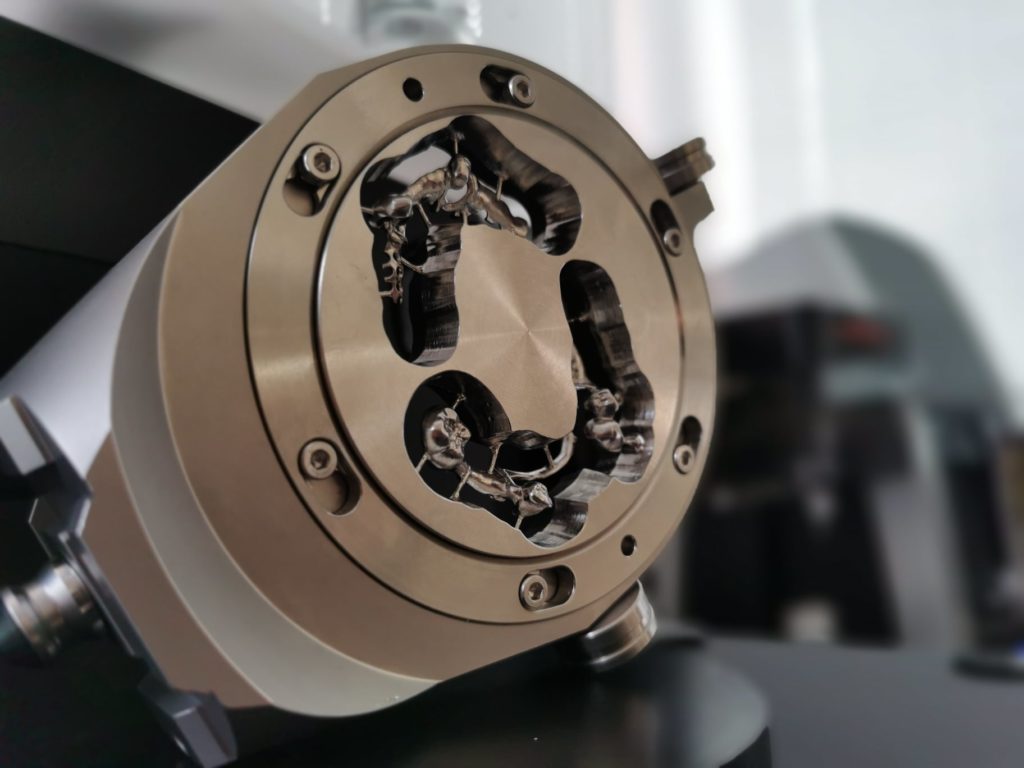

Was immer Sie auch fräsen möchten. hyperdent kennt keine Grenzen!

Dieses Beispiel wurde auf einer imes-icore CORiTEC 350i PRO+ hergestellt.

FOLLOW-ME! Osteraktion – hyperDENT Compact New Upgrade

hyperDENT Experten aufgepasst!

Mit unserer Osteraktion profitieren Sie ab heute bis einschließlich Ostermontag beim Upgrade Ihrer veralteten hyperDENT Lizenz auf die hyperDENT Compact NEW!

Die Fertigung effizienter zu gestalten und Durchlaufzeiten von Teilen zu verkürzen ist ein stetiges Ziel unserer Kunden und Partner. FOLLOW-ME! möchte diesem Anspruch gerecht werden und Ihnen darüber hinaus noch deutlich mehr bieten. Vorrangiges Ziel ist es daher, hyperDENT zukunftsweisend weiterzuentwickeln.

Durch den hohen Grad an Automatisierung sparen Sie viel Zeit und Geld in Ihrem Fertigungsprozess.

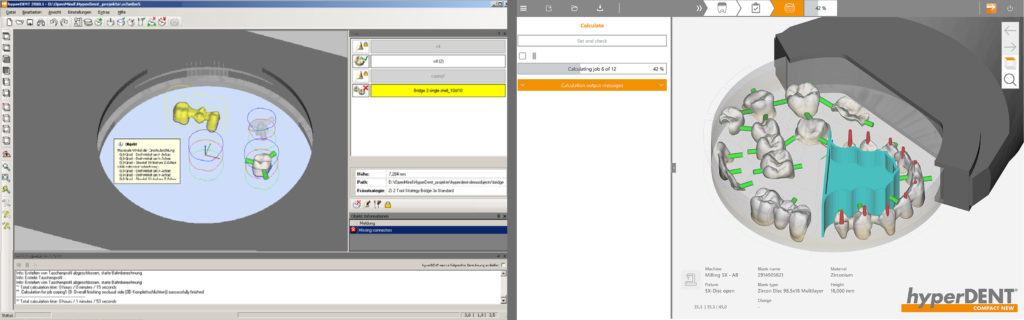

Im Rückblick auf frühere Versionen wird unser Anspruch deutlich. Auch wenn wir schon damals Maßstäbe in der digitalen Dentalfertigung gesetzt haben, sprechen wir bei der neuesten hyperDENT Generation von einem großen Meilenstein in unserer Geschichte.

links: hyperDENT früher – rechts: hyperDENT heute

Das Design der hyperDENT Compact Benutzeroberfläche passt sich vollständig den Bedürfnissen des Anwenders an. Ein hoher Automatisierungsgrad wird zum einen durch die stark vereinfachte Oberfläche und zum anderen durch den geführten Workflow erreicht. So kann die Berechnung eines Projekts in nur drei Schritten abgeschlossen werden, wobei dem Anwender immer der aktuelle Bearbeitungsschritt angezeigt wird.

DATRON Dental Show 2021!

Wir sind zu Gast bei der virtuellen DATRON Dental Show 2021!

Wir schenken Ihnen -20%

Unser Partner DATRON AG veranstaltet die

DATRON Dental Show 2021 vom 09. – 13. März 2021.

Wir freuen uns sehr, bei diesem Event dabei zu sein und unsere zukunftsweisende Technologie der Hybridfertigung im „Video-on-Demand“ Bereich

unter „Dentale CAD/CAM Hybridfertigung“ zu präsentieren.

Diese Fertigungstechnologie haben wir in Kooperation mit der DATRON AG von der Grundlagenforschung bis zur Marktreife gebracht.

Holen Sie sich auf diesem kostenlosen Online-Event der „DATRON Dental Show“ interessante Insights zum hybriden Fertigungsprozess.