FOLLOW-ME! News

hyperDENT exocad Connect

Vollständige CAM-Software-Integration in exocad

exocad ChairsideCAD bietet in Kombination mit hyperDENT exocad Connect auf jeder geeigneten Maschine eine nahtlose CAM-Anbindung zur direkten Fertigung dentaler Werkstücke.

Für die Bearbeitung der entworfenen Zahnrestaurationen benötigt der Anwender keine CAM-Erfahrung, da hyperDENT exocad Connect vollautomatisch im Hintergrund von exocad ChairsideCAD arbeitet.

„Unsere leistungsstarke Software ChairsideCAD, die kürzlich in den USA bereits zum zweiten Mal mit dem renommierten Cellerant „Best of Class” Technology Award ausgezeichnet wurde, zeichnet sich durch einen hohen Automatisierungsgrad und benutzerfreundlichen Workflow aus“, erläutert Novica Savic, CCO bei exocad, und weiter: „Die Integration mit hyperDENT bietet den Anwendern höchste Flexibilität und Leistung für Restaurationen in nur einer Patientensitzung.“

Allen Maschinenherstellern wird zudem die Möglichkeit geboten, sich in die Schnittstelle von exocad ChairsideCAD und hyperDENT exocad Connect zu integrieren und diese an die eigenen Bedürfnisse anzupassen.

Erfahrener CAD/CAM-Zahntechniker:

„Dies ist der nächste Schritt in Richtung plattformübergreifendes Scannen und Fertigen in der Dentalbranche. Der Anwender hat die Freiheit Maschine und Anwendungen für eine High-End-Fertigung frei zu wählen und diese in einem Workflow miteinander zu vereinen.“

Christmas Special ADDITIVE ONLY

Additive Fertigung für die Dentalindustrie

Sind Sie mit Ihrer 3D-Druck-Software unzufrieden? Dann haben wir genau die richtige Lösung für Sie!

Bereiten Sie sich auf die Zukunft der Dentalindustrie vor!

Mit unserem All-Inklusiv-Weihnachtspaket erhalten Sie einen Rabatt von 25% auf die FOLLOW-ME! Additive Manufacturing Software!

Aktion gültig vom 01.12.2020 – 18.12.2020

| “Additive Only” Paket | inklusive |

| Installation und Training | ✓ |

| Software-Updates für 1 Jahr | ✓ |

| Software-Support für 1 Jahr | ✓ |

| Ausgabeformat für Ihren 3D-Drucker | ✓ |

| Upgrade auf Hybrid möglich | ✓ |

Kontaktieren Sie noch heute Ihren hyperDENT Händler oder sales@fm-dental.com und profitieren Sie von erstklassiger Performance, die Sie nur bei FOLLOW-ME finden!

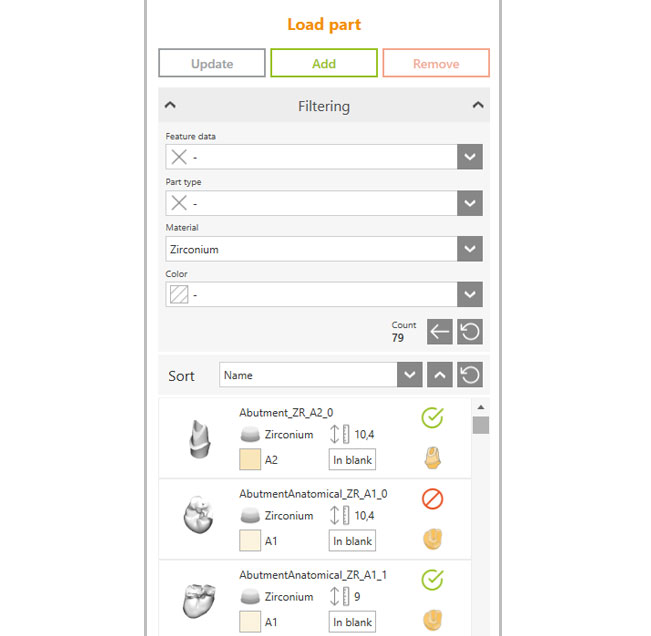

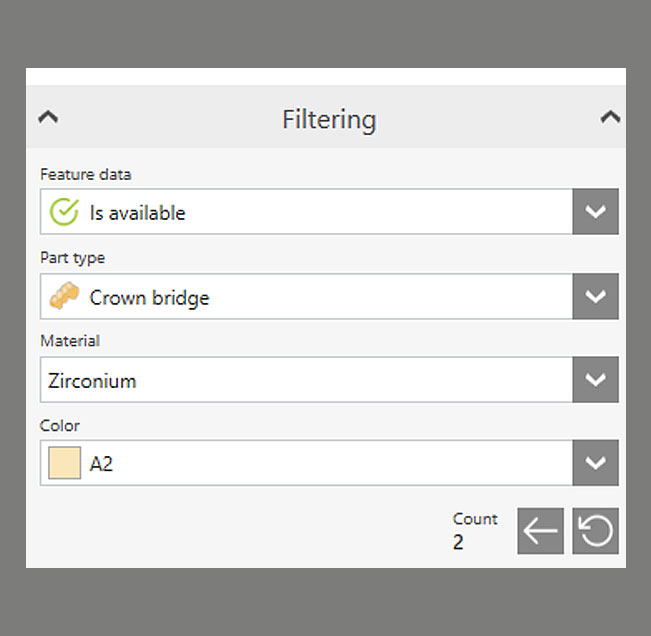

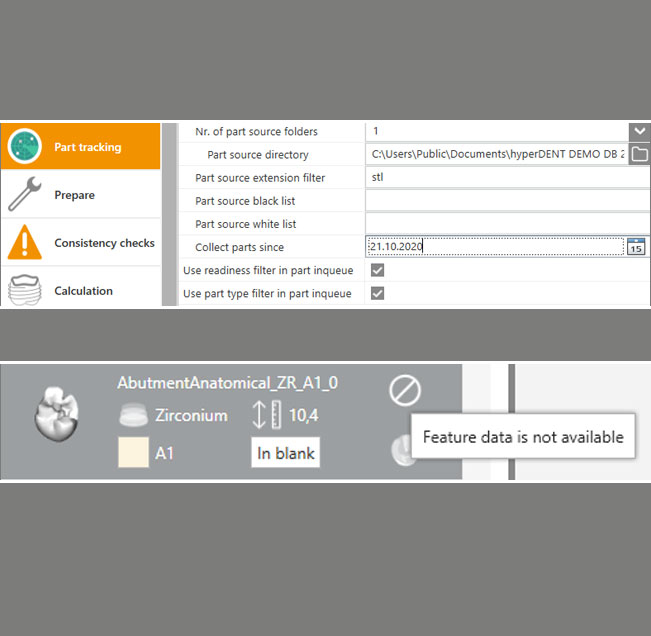

hyperDENT Toolbox – Teilemanager (Part Inqueue)

Die Funktion „Automatisches Füllen der Objektliste“ ermöglicht eine direkte Verknüpfung von hyperDENT mit dem Ausgabeordner des CAD-Systems.

In einer übersichtlichen Liste können sowohl die noch zu produzierenden Teile, als auch weitere Zusatzinformationen wie beispielsweise die Materialeigenschaften, die Höhe und Teiletypen angezeigt werden.

In diesem Video erklären wir Ihnen wie Sie hyperDENT mit Ihrem CAD-System verknüpfen können und zeigen Ihnen die sich daraus ergebenden Vorteile für die Beschleunigung ihres Fertigungsworkflows.

Mehr Freiheiten im Produktionsprozess durch Innovationen von FOLLOW-ME!