FOLLOW-ME! News

Dentale Hybridfertigung

Dentale Hybridfertigung – Ein echtes Highlight für unseren Nachwuchs im GE Additive Customer Experience Center

hyperDENT V9.1 – Freiheit durch Innovation gestalten.

Sehr geehrte Damen und Herren,

unsere Entwicklungsabteilung hat kontinuierlich an einer Reihe neuer Funktionen und Verbesserungen gearbeitet und diese in die neue hyperDENT Version 9.1 implementiert. Wir haben es uns zum Ziel gesetzt, ihre Arbeitsprozesse weiterhin deutlich zu beschleunigen. Neben den zahlreichen Erweiterungen und Verbesserungen der Standard-Funktionen, finden Sie in der aktuellsten Version V9.1 viele neue und weiterentwickelte Automatisierungsmöglichkeiten. Diese helfen ihnen interne Arbeitsabläufe zu beschleunigen und somit viel Zeit und Kosten zu sparen.

So macht das Arbeiten Spaß!

hyperDENT Webinar-Reihe Automation

3. Webinar Automation (Deutsch)

Freitag, 29.05.2020 :: 10:00 Uhr

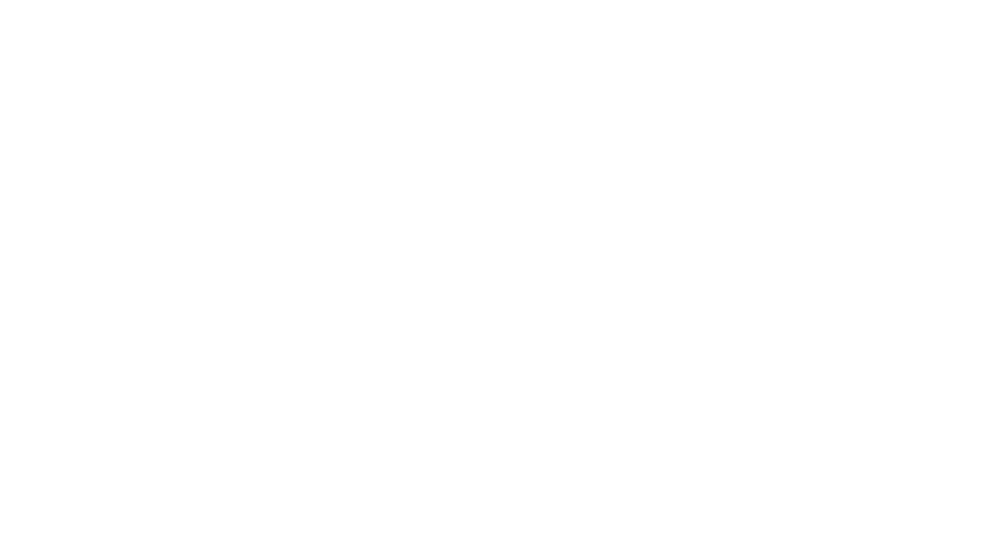

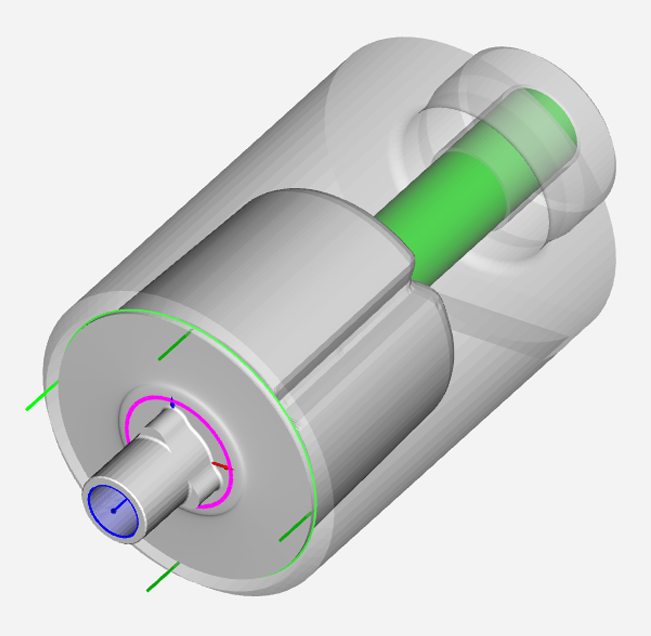

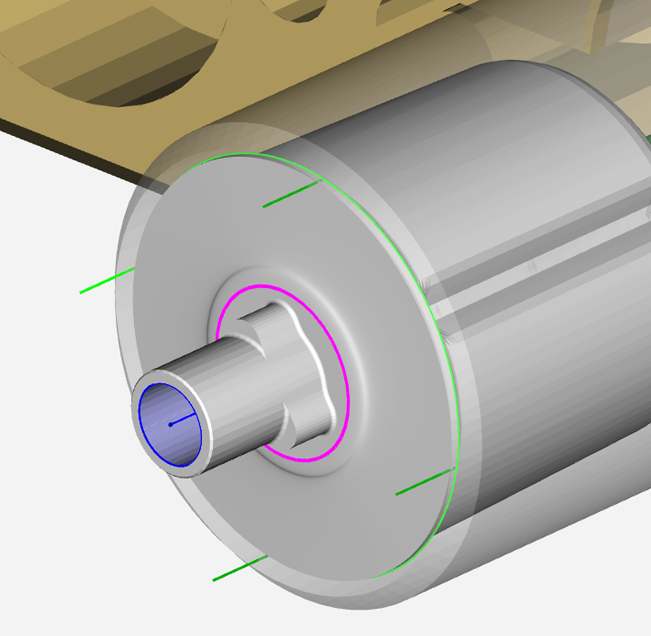

Automatisierte Preform-Fertigung

Der manuelle Preform-Workflow ist in der Regel den meisten hyperDENT Anwendern geläufig. Wie sieht es aber mit der automatisierten Selektion von Preform-Rohlingen und der automatischen Positionierung von STL-Modellen im Rohteil aus? Alle Antworten hierzu geben wir in diesem Webinar.

Jeder Teilnehmer erhält nach erfolgreicher Anmeldung über Zoom eine E-Mail-Bestätigung mit Link und Login-Daten zur Teilnahme am jeweiligen Webinar.

Mit der Teilnahme am Webinar stimmen Sie unseren AGB, der Verarbeitung und Nutzung Ihrer Daten für andere Zwecke, insb. zu Beratungs-, Werbe- und Marktforschungszwecken zu.

Ihr FOLLOW-ME! Team