FOLLOW-ME! News

hyperDENT V9.2 Release Updates

Unsere Entwicklungsabteilung hat kontinuierlich an einer Reihe neuer Funktionen und Verbesserungen gearbeitet und diese in die neue hyperDENT Version 9.2 implementiert. Wir haben es uns zum Ziel gesetzt, ihre Arbeitsprozesse weiterhin deutlich zu beschleunigen. Neben den zahlreichen Erweiterungen und Verbesserungen der Standard-Funktionen, finden Sie in der aktuellsten Version V9.2 viele neue und weiterentwickelte Funktionen. Diese helfen ihnen interne Arbeitsabläufe zu beschleunigen und somit viel Zeit und Kosten zu sparen.

So macht das Arbeiten Spaß!

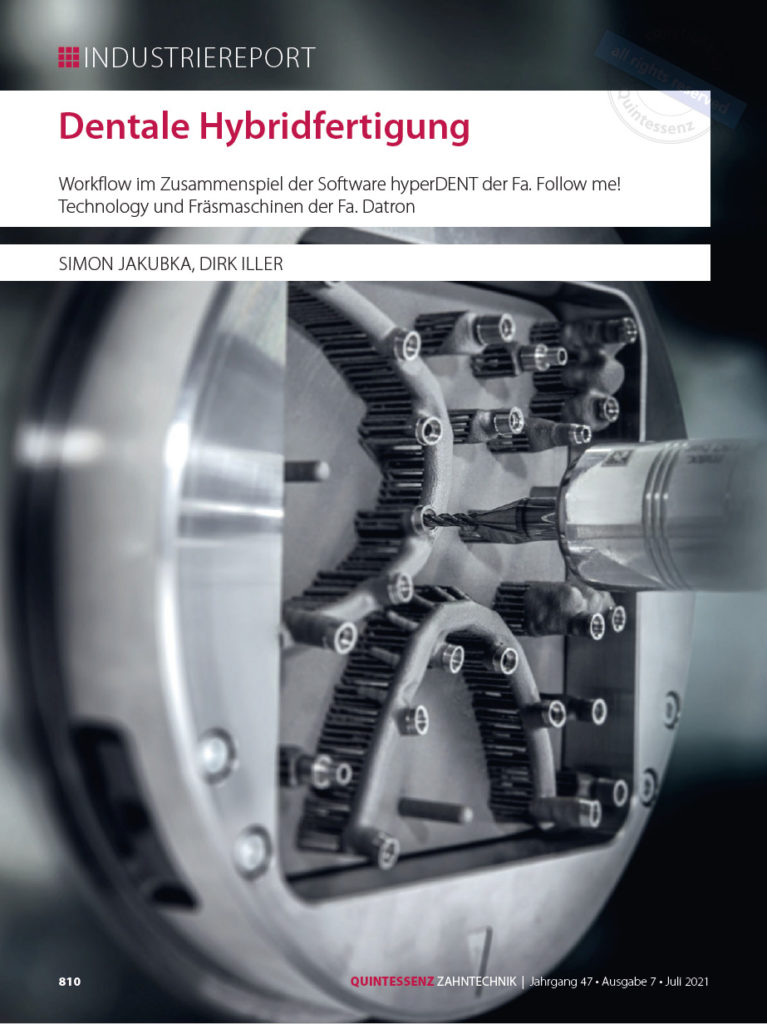

Industriereport: Dentale Hybridfertigung

Zusammenfassung:

Auch wenn die additive Fertigung immer mehr Einzug in die zahntechnischen Labore hält, ist sie doch immer noch mit Nachteilen verbunden, wie eine zu hohe Toleranz im Bauprozess. Der Beitrag stellt eine sogenannte Hybridfertigung der Fa. FOLLOW-ME! Technology (München) und der Fa. DATRON (Mühltal) vor, die trotz hoher Anschaffungskosten hilft, bei der Herstellung von Implantatsuprastrukturen und Teleskopsekundärkronen bis zu 40 Prozent Herstellungskosten einzusparen.

Download INDUSTRIEREPORT „Dentale Hybridfertigung“ als PDF

Jakubka, S.; Iller, D. (2021). Industriereport: Dentale Hybridfertigung. In: QZ – Quintessenz Zahntechnik. Jahrgang 47, 07/2021. Berlin: Quintessenz Verlags-GmbH, S. 810 – 815.

Hufschmied Dental-Workshop

08.07.2021 | 09:00 Uhr – 15:00 Uhr

Workshop: Dental

Neue Dental-Line Werkzeuge

Hochpräzise Werkzeuge für optimale Bearbeitungsergebnisse

Zeitersparnis im Fräsen, Messen und Programmieren

Fachvorträge von:

- Nacera

Nacera® Pearl Natural – die ästhetische Evolution von Zirkonoxid - hyperDENT

Die FOLLOW-ME! Technology Group entwickelt und vertreibt hyperDENT, eines der weltweit führenden Softwaresysteme im dentalen CAM-Markt - Scheftner

Herstellung von Fräsrohlingen in einem speziellen, eigens entwickeltem Gussverfahren

Bearbeitung verschiedener Restaurationen:

- Teleskopkronen, Sekundärteile:

Werkzeuge: HC634DT, HC632DT

Material: Scheftner CoCr (MoguCera C, Starbond Easy, Starbond CoS)

Maschine: Primacon

- Steg mit Anschlussgeometrie:

Werkzeuge: HC632TDT

Material: Scheftner Titan (Starbond Ti5)

Maschine: Primacon

- 6-gliedrige Brücke:

Werkzeuge: Zirkonator, HC720DTA

Material: Nacera® Zirkonoxid (Nacera® Pearl Natural)

Maschine: Primacon und Redon

- Aligner:

Werkzeuge: 110FPRDTA

Material: PMMA

Maschine: Grob

Weitere Themen:

- Der Zirkonator – Zeitersparnis durch Schruppen und Schlichten in nur einem Arbeitsschritt

- Die Bearbeitung von schwer zerspanbaren Materialien ohne Microchipping

- Abstimmung von Geometrie, Materialien und Beschichtung

bei der Werkzeugentwicklung für die Dentalbranche - Kombination aus angepassten Werkzeugen, dem besten Material, den richtigen Frässtrategien und einem optimierten Workflow für das Maximum aus Ihrer Maschine

- Optimierung Ihrer Prozesse in Geschwindigkeit und Qualität

- Durch Zeitersparnis kostengünstigere Herstellungen