New flexibilities for CAD/CAM implant restorations in hyperDENT® V7.4

FOLLOW-ME! Technology Group, has released its’ hyperDENT® V7.4 software. The new version contains the much anticipated Angulated Screw Channel (ASC) Module which allows for increased functionality and flexibility for in-house implant production.

Efforts between FOLLOW-ME! and Spain based Dynamic Abutment Solutions®, a global dental material systems supplier led to the development of the new hyperDENT module. “Marrying the hyperDENT dental CAM software with the open solution system of Dynamic Abutment Solutions, will open the door to new market opportunities for dental laboratories, as well as a wide range of treatment options for dentists and their patients,” says Dr. Ferdinand Schwenkert, CEO, FOLLOW-ME! Technology Group.

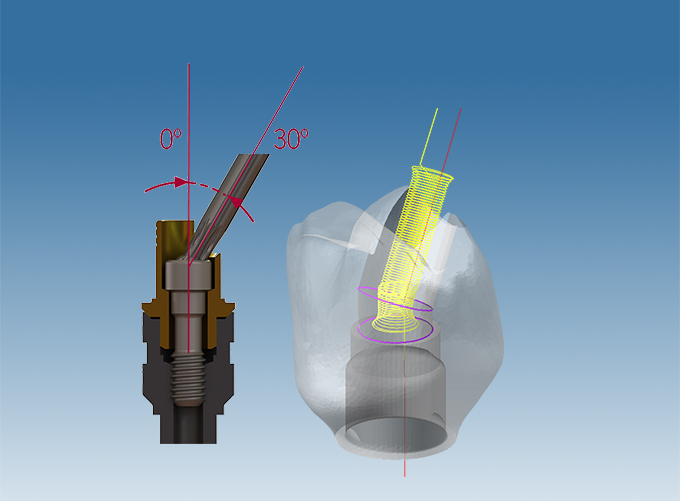

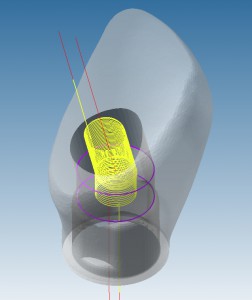

The new ASC Module will provide the ability to drill a screw access hole on an angle of up to 30 degrees for any given prosthesis, allowing dentists to place implants in a more ideal position than was previously possible.

Using existing hyperDENT software and milling equipment, dental laboratories and milling centres can now offer similar high-end features on their implant based restorations just as any implant manufacturer. This then opens up new opportunities for hyperDENT users to tap in to a new customer base.

“There are several issues that dentists face when dental labs are only able to provide prosthesis with a straight angle channel,” explains Mr. Esteban Xam-mar, CEO, Dynamic Abutment Solutions. “Overall, dentists are not able to provide their patients with a truly effective treatment plan, as they are restricted in optimizing the placement of the implant as well as providing the patient with an aesthetically pleasing result.”

Often, the placement of the prosthetic is compromised when having to take the bone structure of the patients’ jaw in to account. With the ASC module, a more accurate angulation can be milled which will provide greater flexibility in allowing the dentist to place the implant in a more ideal position.

“We are obviously very pleased about the partnership between FOLLOW-ME! Technology and Dynamic Abutment Solutions, as it means that together we can provide more freedom and flexibility to dental technicians, dentists and patients. The market has been waiting for a solution like this, and it will therefore open up a steady flow of business opportunities for many dental labs and milling centers,” concluded Dr. Schwenkert.

In many cases, in particular where aesthetics is a strong predetermining factor, cementing a crown on top of an implant was required. This then restricted post-implant treatment options, as more often than not, the initial crown would need to be destroyed and a new one created. This not only caused more time and discomfort for patients, but also extensive monetary costs. With ASC Options Module, crowns and implants are easily retrievable and post restorations can be performed requiring less in-chair patient treatment.

Another problematic aesthetic factor is the lack of ability to be able to provide the patient with a natural colour representation. “When anterior screw channel needs to be filled, it is very difficult to be able to blend the restoration, often leaving patients feeling self-conscious or opting for a cemented porcelain crown,” said Mr. Esteban Xam-mar.

Dentists and technicians will be able to provide both quality crowns together with idyllic positioning and aesthetic placement due to the new-found flexibilities that will be delivered with ASC Module.

hyperDENT V7 was released late last year, and the new ASC Module will be available in hyperDENT V7.4, with only a simple software update required.