FOLLOW-ME! News

Formnext 2022

IDEM 2022

IDEM provided a platform for our company and we meet some of our current clients and partners around the world. Enhance collaboration, exchange ideas to tackle new challenges and explore the latest market trends to help us maintain competence, update and advance our knowledge and skills, and ensure we are the world’s leading dental software hyperDENT.

Your FOLLOW-ME! Team, Singapore

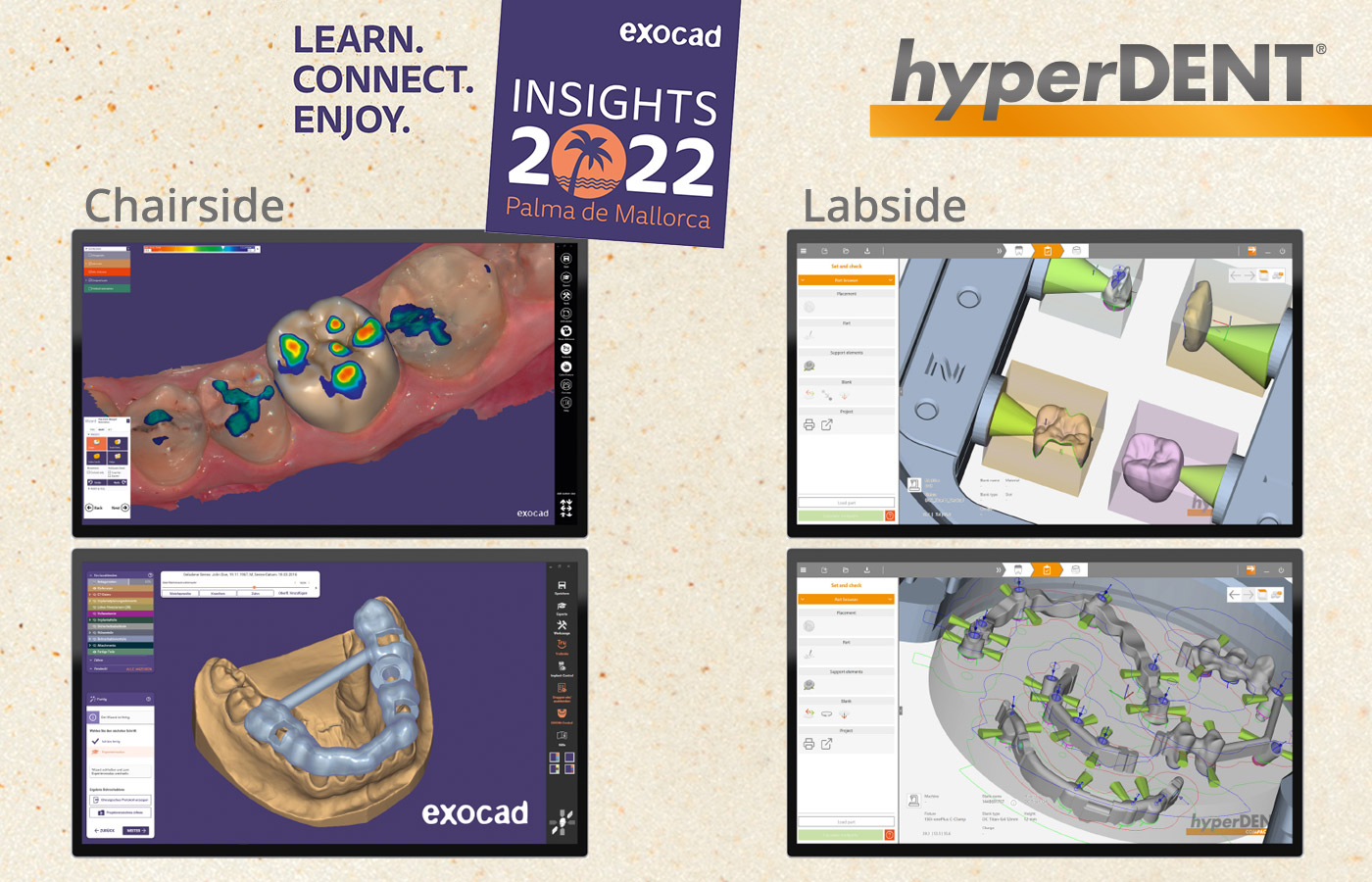

FOLLOW-ME! at exocad Insights Mallorca 2022

We are excited to present you our innovative Chairside and Labside solutions at exocad Insights event October 3-4, 2022, on the sun-drenched island of Mallorca, Spain.

Chairside

hyperDENT exocad ChairsideCAD is our fully integrated blackbox solution wihin exocad.

„The integration of hyperDENT offers users the highest degree of flexibility and performance single-visit dentistry.”

Novica Savic, CCO at exocad

Labside

hyperDENT Compact is our solution for all dental lab milling machines.

„The simplified user interface with a managed workflow offers real added value to our customers.“

Dr. Ferdinand Schwenkert, CEO at FOLLOW-ME!

Formnext

15. – 18. November 2022 | Frankfurt am Main

As the leading industry platform for additive manufacturing and industrial 3D printing, Formnext is the international meeting point for the next generation of intelligent industrial production.