FOLLOW-ME! News

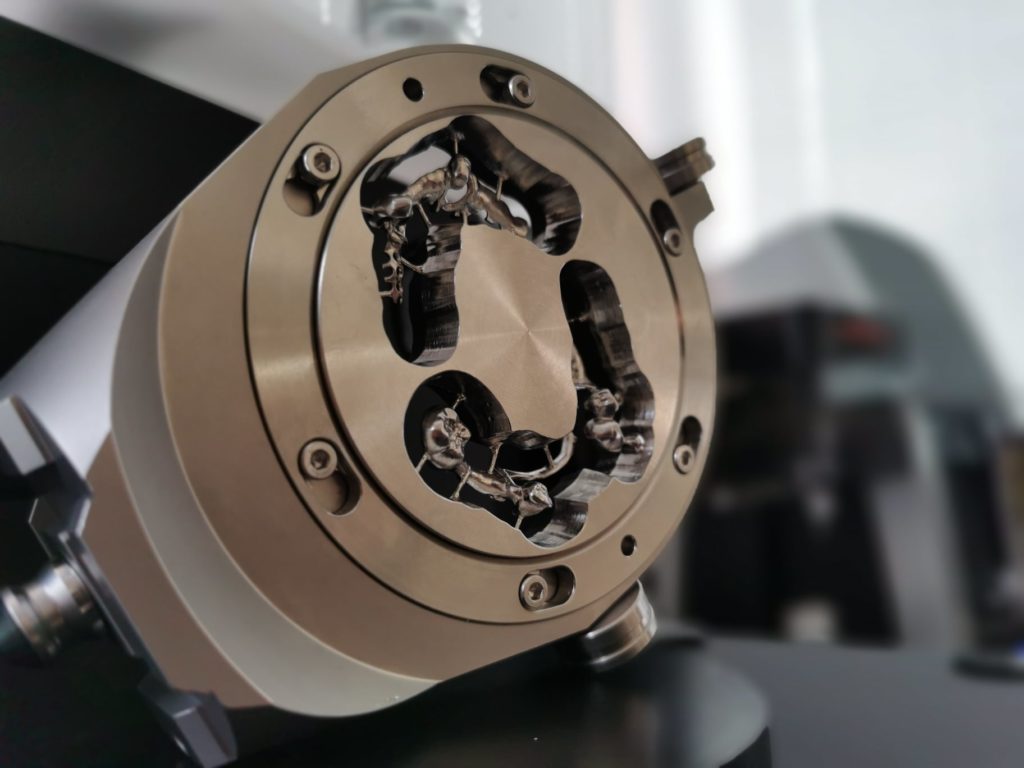

Best results with hyperDENT & imes-icore machines

Whatever you want to mill. hyperdent knows no limits!

This example was created on an imes-icore CORiTEC 350i PRO+

FOLLOW-ME! Easter Offer – hyperDENT Compact New Upgrade

Attention hyperDENT Experts!

Take advantage of our Easter Offer and upgrade your old hyperDENT license to a hyperDENT Compact NEW license. This special offer is valid from today until Easter Monday (05. April).

Our customers and partners are continuously striving for a more efficient and less time intensive production of parts. FOLLOW-ME! wants to help you achieve this goal and offer even more by ensuring that hyperDENT is developed with a view towards the future.

You will save time and money due to the high level of automation in your milling process.

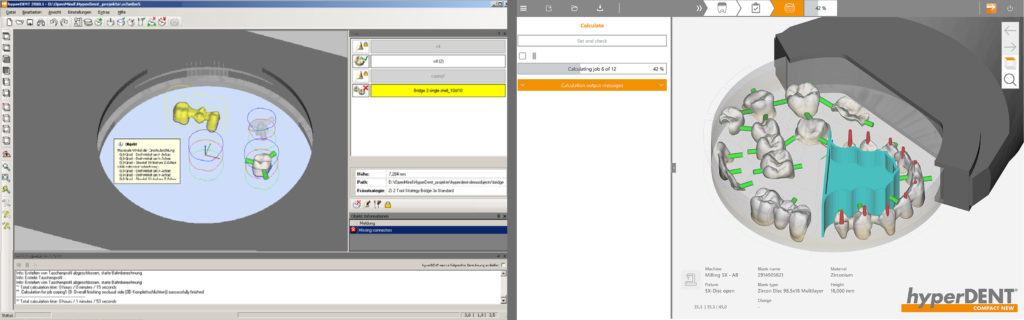

Looking back on earlier versions, our aspirations are clear. Although we set standards for digital dental production then, the current hyperDENT generation marks a big milestone in our company history.

left: hyperDENT earlier – right: hyperDENT today

The hyperDENT Compact user interface is designed to match user requirements completely. Increased automation is achieved by the greatly simplified interface as well as the guided workflow. The project calculation can be completed in only three steps with the current processing step always in view.

DATRON Dental Show 2021!

We have been invited to participate in the virtual DATRON Dental Show 2021!

We are offering a -20% discount

Our partner DATRON AG is hosting the

DATRON Dental Show 2021 from 09. – 13. March 2021.

We are very pleased to participate in this event and to present our pioneering hybrid manufacturing technology in the “Video on Demand” area under “Dental CAD/CAM Hybrid Manufacturing”.

We developed this manufacturing technology in cooperation with DATRON AG from the fundamental research phase to a market-ready product.

Take advantage of this free “DATRON Dental Show” online event to obtain interesting insights about the hybrid manufacturing process.